Rubber Fuel Seal – How to Design the Perfect One?

There are a few factors that need to be kept in mind when designing fuel seals.

- Temperature ranges that the given rubber variants can work in: Fuel seals are made up of different types of rubber. The kind of rubber variants used for a particular fuel seal depends upon the type of fuel used in the application. Not all rubber variants can work in the same temperature ranges and fuels. Only one or two type of rubber is suitable as fuel seals material for each of the application. It is important therefore to take into consideration the kind of temperature ranges that the chosen rubber variant can work in when choosing the same for fuel seals.

- Maximum temperature required: The kind of exposure to the temperature that the application involves is one of the most important factors in designing the fuel seals. Other than the kind of temperature range the application calls for, the highest degree of temperature that may be required for the same is also one of the most important considerations.

- Resistance to fluids: Fuel seals are used for resisting fuels. It is important to take into account how the fluids used in applications would behave in high and low temperatures and design the fuel seals likewise.

- Expert advice: One should not choose the fuel seals randomly; it is important to get expert scientific advice on the matter. Thermal expansion, out gassing and chemical background are all such factors that need to be taken into account for each of the application when choosing the material for fuel seals.

- Necessity

for the margin: It is also important that one keeps a little margin either ways

of the temperature range when choosing the polymer for the fuel seal.

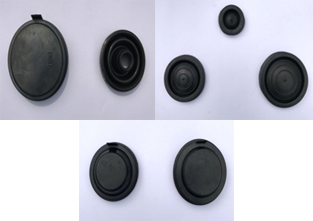

Alfa Rubber is one of the leading companies in India crafting

high quality fuel seals across a variety of polymers.

For

More Details:

ALFA RUBBER & SPRINGS PRIVATE

LIMITED

GUMMIDIPOONDI

TAMILNADU

TELEPHONE – +91-44-27922057

EMAIL – info@alfarubber.com

Website: http://alfarubber.com/

.jpg)

Comments

Post a Comment