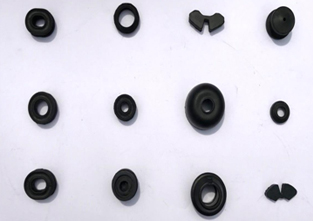

Rubber O-ring manufacturer in Tamil Nadu – Delivering customized solutions

Rubber O-rings are mechanical gaskets used to prevent

leaks in gas and fluids. It is manufactured from different types of elastomers.

There are many types of O-ring materials and these include:

1.

Neoprene

2.

Nitrile

3.

PTFE

4.

RPDM Rubber

5.

Fluorocarbon

6.

Silicone

For high temperature applications Silicone is commonly

used. Rubber

O-ring manufacturers in Tamil Nadu delivers both custom standard and

industry standards. The size may vary depending on the type of the product

selected. The O-rings are available in different size, materials, profiles and

durometers.

O-Ring

material selection

There are many types of materials available and each has

different applications and features. Certain materials improve performance in

high heat and chemical applications while others deteriorate under tough

operating conditions. The O ring compatibility is determined by the type of

chemicals and oils used. Both tear resistance and abrasion is important

especially in dynamic applications.

Primary

considerations of O ring material selection

1.

Temperature compatibility

2.

Durometer

3.

Size

4.

Cost

5.

Chemical compatibility

6.

Sealing pressure

Based on the applications, electrical properties, tear

resistance, dynamic resistance and ozone resistance are considered. The

parameters are taken into consideration while making a choice.

Types of O-Ring applications and their impact

1.

Static Axial Seal groove is designed after

taking into consideration the pressure coming from inward or outward. For

outward pressure the outside diameter is considered and for inward pressure,

inside diameter is crucial.

2.

Reciprocating dynamic seals are used for

pneumatic or hydraulic piston. For short strike smaller diameter is used and

for longer stroke thicker cross section is used.

3.

Rotary seals are reliable under adequate

conditions like durometer, feet per minute values and hardware configuration

matches. For shaft hardness value of 55 Rockwell is required for the success of

the O-Ring. There are specialized O-Ring compounds for rotary service.

GET IN TOUCH WITH

US:

ALFA RUBBER & SPRINGS PRIVATE LIMITED

A-13/A, SIPCOT INDUSTRIAL COMPLEX,

GUMMIDIPOONDI. TAMILNADU

601 201, INDIA

PHONE : +91-44-27922057

WEBSITE : http://alfarubber.com/

EMAIL : info@alfarubber.com

Comments

Post a Comment